FOCUS-1 vs. traditional control loops: What’s the difference?

George Borst

Responsable du développement commercial

March 7, 2025

The process industry has long relied on complex automation systems to regulate flow, pressure, and temperature. Traditional control loops require multiple components, leading to high costs, inefficiencies, and a lot of maintenance.

Each component requires its own installation, programming, and upkeep, adding layers of complexity to process automation. But what if there was a simpler, smarter way to manage process control? This blog explains.

The traditional control loop: A complicated setup

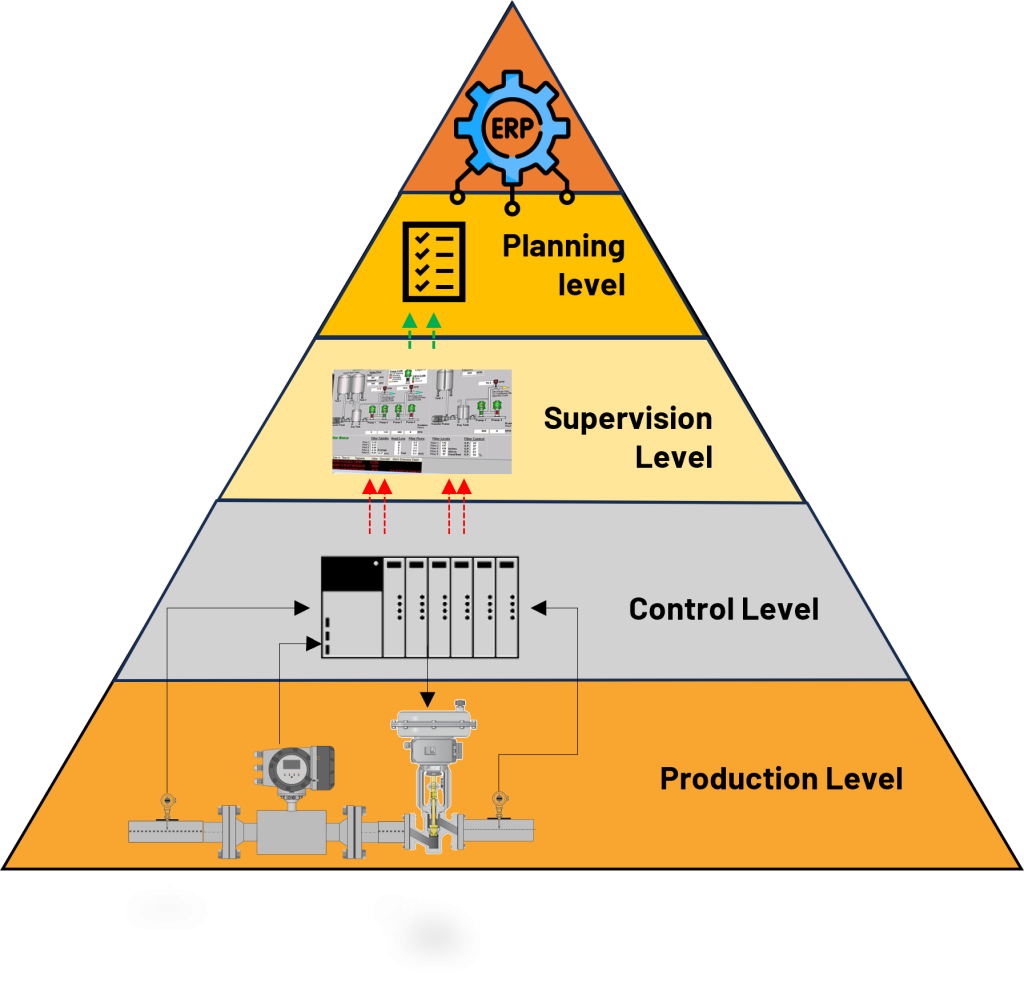

Conventional process automation follows the automation pyramid, a hierarchical structure designed to ensure efficiency but often leading to operational bottlenecks.

- Field Level: This includes flow meters, pressure and temperature sensors, and control valves that interact directly with the physical process.

- Control Level: Uses PLCs (Programmable Logic Controllers), DCS (Distributed Control Systems), and PID controllers to regulate process parameters. This level ensures that the system maintains the desired conditions.

- Supervision Level: Comprises SCADA (Supervisory Control and Data Acquisition) systems, HMI (Human-Machine Interfaces), and asset performance monitoring tools. It provides oversight and a digital representation of process operations.

While this structure is effective, it has several drawbacks:

- Each additional sensor or control device increases the complexity of the system.

- More devices mean more potential failure points, increasing maintenance and des arrêts prolongés.

- Integration between devices from different manufacturers can cause inefficiencies.

- High installation costs due to excessive cabling, wiring, and programming requirements.

How FOCUS-1 simplifies process automation

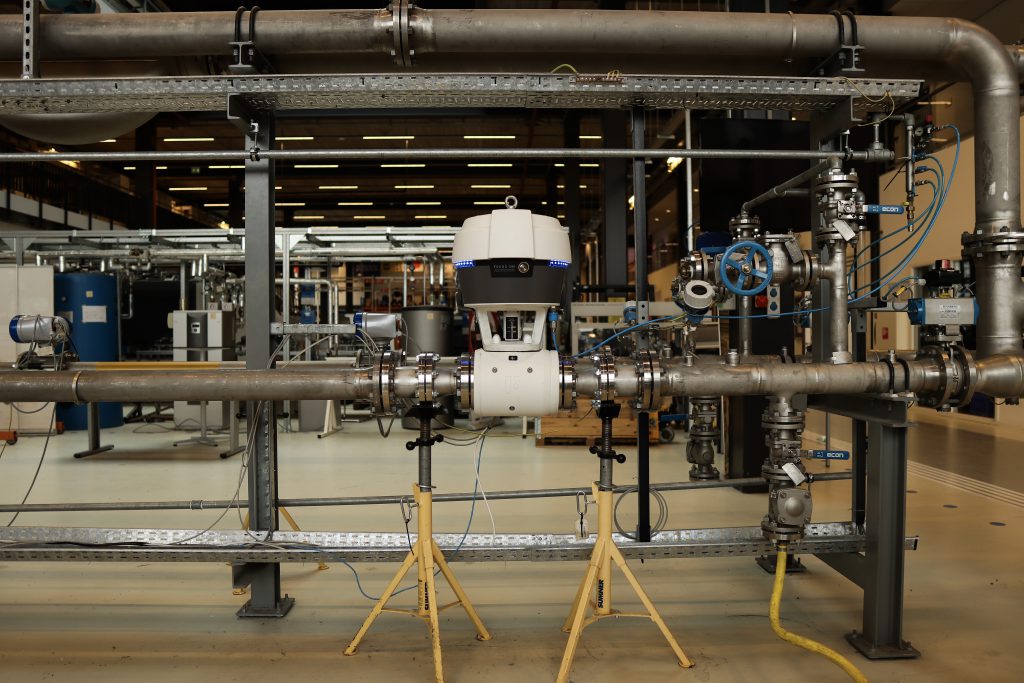

FOCUS-1 represents a paradigm shift in process control. Instead of relying on multiple separate components, it integrates various essential functions into a single smart device, effectively eliminating the need for numerous discrete instruments.

- Replaces multiple components: Flow meters, pressure and temperature sensors, control valves, and even PID controllers are consolidated into one device.

- Shifts PID control from the control level to the field level: This means control calculations are done directly within FOCUS-1, eliminating the need for external PID controllers and reducing the computational load on PLCs and DCS.

- Simplifies installation and maintenance: With fewer components, the installation process is more straightforward. Fewer cables and flanges mean reduced material costs and shorter setup times. This also results in fewer potential failure points, minimizing the need for ongoing maintenance.

- Improves data integration and communication: The FOCUS-1 seamlessly integrates into existing automation systems and uses standard industrial communication protocols to relay data, ensuring compatibility and smooth operations.

By reducing the number of components needed, the FOCUS-1 not only cuts installation costs but also decreases operational des arrêts prolongés. Since it combines measurement, control, and computing power in one device, industries can operate with greater accuracy, efficiency, and reliability while reducing the overall footprint of their automation systems.

Real-world benefits of FOCUS-1

Industries that have adopted FOCUS-1 have reported:

- Significant cost savings on procurement and installation due to fewer components and reduced wiring complexity.

- Increased operational efficiency due to real-time control adjustments and better system integration.

- Lower maintenance costs since fewer devices mean fewer points of failure and reduced system complexity.

- Improved process reliability, as the built-in computing power allows for predictive maintenance and early detection of potential failures.

A key factor contributing to these benefits is that FOCUS-1 eliminates the need for multiple flanges, cables, I/O points, and PID programming. This results in 33% savings on installation, reducing the overall cost of ownership.

Read more case studies here.

How FOCUS-1 supports sustainability

Beyond cost and efficiency savings, FOCUS-1 also contributes to more sustainable operations. By reducing the number of devices, it minimizes energy consumption and raw material use. Additionally, its predictive maintenance capabilities help prevent unnecessary shutdowns and optimize resource use, making industrial processes more environmentally friendly.

Conclusion

FOCUS-1 revolutionizes process automation by reducing complexity, costs, and inefficiencies. By integrating measurement and control into a single device, it eliminates the need for multiple components, simplifying operations while enhancing accuracy and reliability.

Book your free consultation call today!

Want to read more about FOCUS-1?

Also make sure to read our blogs about: