Dynea, a leading player in Europe’s wood adhesives sector, champions wood use in construction to bolster global CO2 storage. Crucial to Dynea’s adhesive manufacturing is efficient steam production, aligned with their sustainability aims of reducing energy consumption. Traditional boiler control systems have struggled to maintain optimal efficiency, prompting Dynea to seek solutions. Let’s introduce FOCUS-1, the world’s first smart meter, pivotal in Dynea’s journey to enhance boiler efficiency. This case studies the challenges posed by traditional systems, highlights the transformative benefits of FOCUS-1, and examines its profound impact on Dynea’s operational and environmental objectives. Explore how FOCUS-1 revolutionized Dynea’s boiler operations and sustainability initiatives.

Inside Dynea’s Boiler Control System Complexities

What are the complexities of boiler feedwater dynamics? Have you ever considered the constraints of conventional control systems? Are you curious to know the innovative solutions that have revolutionized the field, including FOCUS-ON’s smart meters? We will start by discussing the difficulties Dynea faces in maintaining optimal boiler performance and the inefficiencies in their current setup.

What You Need to Know About Boilers

Boiler feedwater is the water supplied to the boiler to generate steam, playing a crucial role in maintaining efficient and reliable operations. The quality and temperature of this water are vital for the boiler’s performance and longevity. Feedwater typically undergoes treatment to remove impurities and meet standards. This prevents issues like scaling, corrosion, and foaming, which can reduce efficiency and cause problems.

During steam production, feedwater is heated and converted into steam for industrial processes. Maintaining a stable feedwater flow is essential for optimal performance. Variations can lead to inefficiencies, increased energy consumption, and potential damage. Understanding boiler feedwater dynamics is key to appreciating the challenges and advancements in boiler control systems, as discussed in this case study.

Insights into Dynea’s Boiler Control Challenges

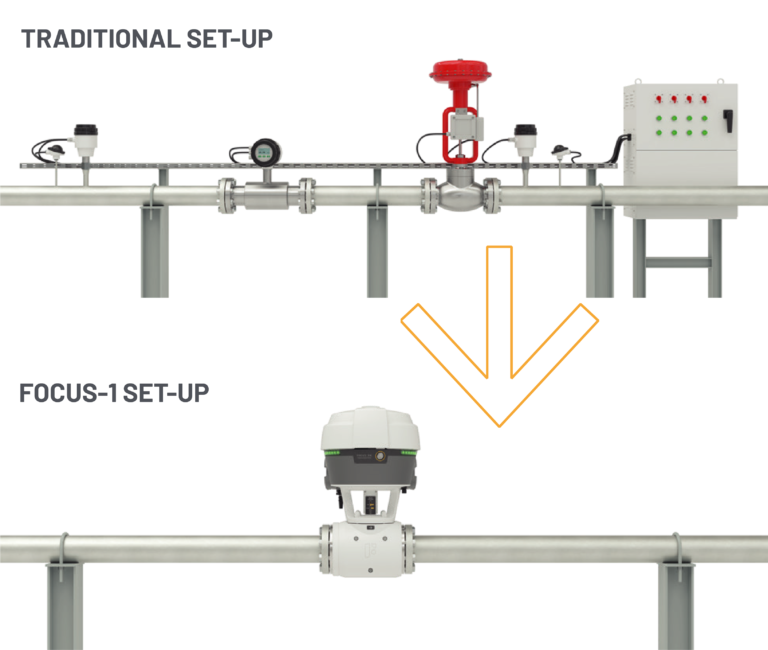

Currently, Dynea uses separate pressure sensors to monitor boiler pressure. If the pressure deviates from the optimal range of +/- 2.3 bar, adjustments are made through a control valve. However, this setup does not provide detailed information on factors such as feedwater temperature and flow rate, limiting opportunities for optimization.

Optimization of Boiler Feedwater

How did Dynea address challenges through FOCUS-1 integration? What insights did enhanced control and monitoring provide? Did you know this led to improved energy efficiency and a reduced carbon footprint? Keep reading if you want to find out what are the tangible benefits of embracing advanced technology in industrial processes.

Enhanced Control & Monitoring with FOCUS-1

Integrating FOCUS-1 provides Dynea with a comprehensive solution for boiler control and monitoring. FOCUS-1 delivers real-time data on flow, pressure, and temperature, empowering Dynea to optimize feedwater usage and improve energy efficiency.

Greater Insights into Boiler Operation

FOCUS-1 offers Dynea unprecedented insights into boiler performance. Detailed data on feedwater dynamics enables Dynea to streamline operations, reduce energy consumption, and minimize their carbon footprint.

Improving Carbon Footprint

Dynea’s adoption of FOCUS-1 results in significant improvements in their carbon footprint. By optimizing feedwater usage and enhancing energy efficiency, Dynea contributes to a more sustainable manufacturing process.

How Did FOCUS-1 Transform Dynea’s Processes?

Interested to know the key benefits Dynea gained from integrating FOCUS-1? Well, by enhancing control and monitoring capabilities, Dynea achieved improved energy efficiency, enhanced operational reliability, and reduced emissions. Let’s explore the specifics of how FOCUS-1 benefited Dynea’s operations:

- FOCUS-1 provides Dynea with comprehensive control and monitoring capabilities, enhancing operational efficiency.

- Improved boiler efficiency is achieved through precise control of flow regimes and scaling.

- Energy-saving and water usage monitoring and reduction are facilitated by FOCUS-1.

- Enhanced boiler performance leads to reliable operation and reduced breakdowns.

- High-efficiency boilers result in lower emissions, contributing positively to environmental sustainability.

Curious About the FOCUS-1 Benefits for You?

Get in touch to talk about the benefits of the FOCUS-1, to plan a demo or to talk about the possibilities of a proof-of-concept!