FOCUS-1 explained: How this all-in-one device replaces traditional control systems

George Borst

Business Development Lead

February 26, 2025

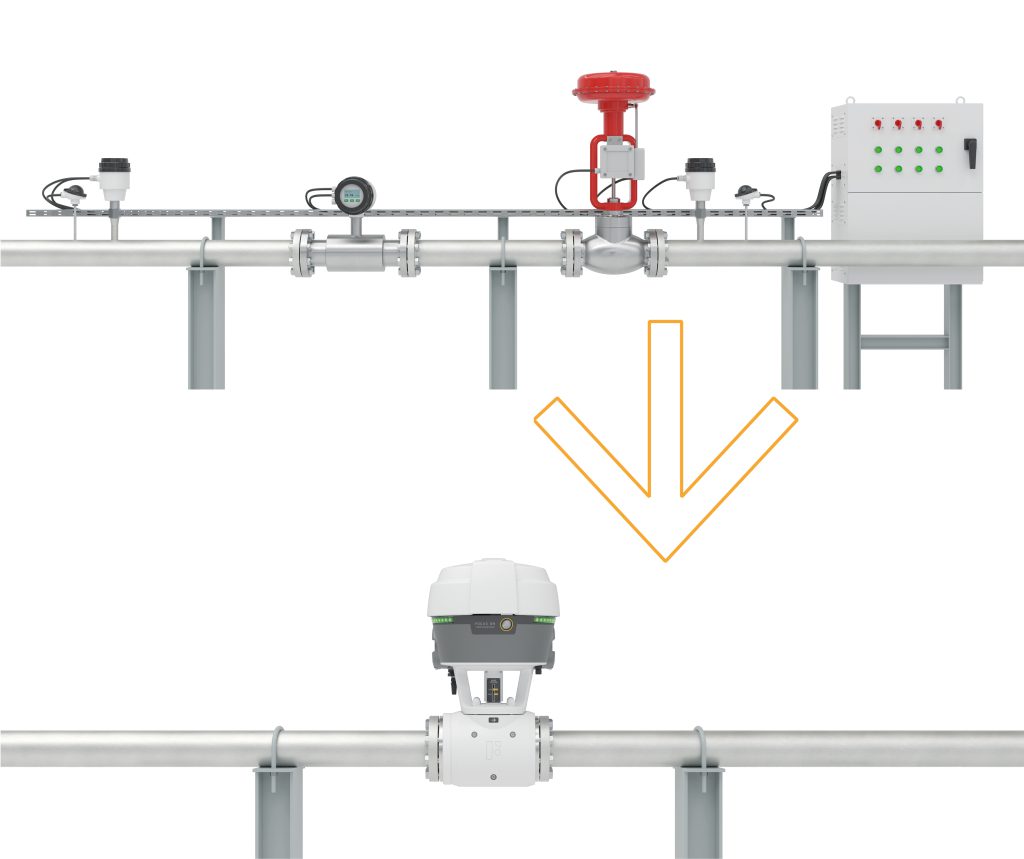

The world of process automation is constantly evolving, with industries seeking more efficient and reliable ways to regulate flow, pressure, and temperature. Traditional setups rely on multiple separate components, each requiring individual installation, calibration, and maintenance.

FOCUS-1 changes this dynamic by integrating measurement, control, and computing power into a single intelligent device. But what exactly is FOCUS-1, and why is it a game-changer in process automation? This blog explains.

What is FOCUS-1?

FOCUS-1 is a Smart Meter Valve, an all-in-one device that integrates several key functions of a conventional control loop into a compact, easy-to-install solution. It was developed through a partnership between SAMSON and KROHNE, two leading manufacturers in industrial automation, combining their expertise in valve technology, measurement solutions, and smart control systems.

Unlike traditional setups that rely on separate flow meters, control valves, pressure and temperature sensors, and external PID controllers, FOCUS-1 consolidates these functions into a single unit. This integration eliminates the need for excessive wiring, flanges, and external controllers, reducing complexity and enhancing efficiency.

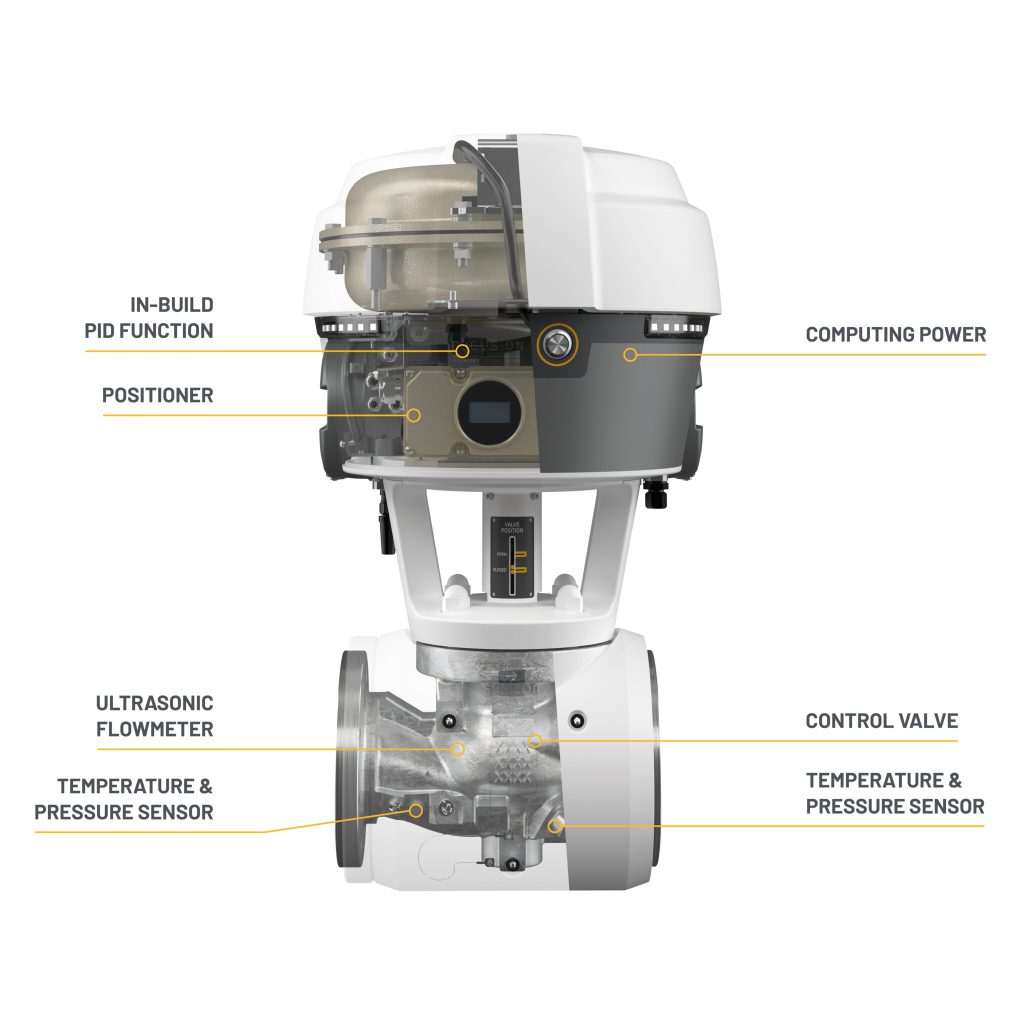

The core components of FOCUS-1

1. Valve technology:

- At its core, FOCUS-1 is built on the SAMSON 3241 control valve, a robust and reliable industrial valve that has been used in process industries for decades.

- The valve body features an integrated actuator and positioner, ensuring precise control over flow, pressure, and temperature.

2. Measurement technology

- The device incorporates KROHNE’s Optisonic 3400 ultrasonic flow meter, allowing accurate and reliable flow measurement.

- Built-in pressure and temperature sensors provide real-time monitoring, eliminating the need for additional external sensors.

3. Computing power and control

- The integrated smart computer connects all components, enabling real-time control and automation.

- Internal PID control eliminates the need for external controllers, simplifying the control loop.

- The smart system allows predictive maintenance, detecting wear and tear before failures occur.

How does FOCUS-1 work?

Traditional process control systems operate by measuring flow, pressure, or temperature separately and sending data to a PID controller at the control level. The controller then calculates adjustments and communicates back to a control valve or pump to regulate the process.

With FOCUS-1, this control process is streamlined and moved to the field level. The integrated computer continuously monitors and adjusts flow, pressure, and temperature, removing the need for external PID controllers. Instead of relying on multiple separate devices to communicate with one another, FOCUS-1 performs all these functions internally, responding in real time and optimizing control loops faster and more efficiently.

Key advantages of FOCUS-1

1. Simplifies system architecture

- Eliminates the need for multiple components and reduces system complexity.

- Reduces installation time, programming effort, and maintenance requirements.

2. Improves accuracy and efficiency

- Integrated sensors provide real-time data, ensuring faster response times and precise control.

- Direct control on flow, pressure, and temperature results in better process stability.

3. Enables predictive maintenance

- The internal computing system continuously monitors process conditions.

- Detects early signs of wear, leaks, or inefficiencies, reducing downtime.

4. Enhances cost savings

- Fewer components mean lower procurement, installation, and maintenance costs.

- Less cabling, flanges, and external controllers contribute to a 33% reduction in installation costs.

5. Supports sustainability goals

- Reduces energy consumption by optimizing process control.

- Minimizes material waste and unnecessary component usage.

Who benefits from FOCUS-1?

FOCUS-1 is designed for industries that rely on precise process control, including:

- Chemical processing: Ensures stable flow and pressure for chemical reactions.

- Food & beverage: Guarantees consistent ingredient mixing and temperature control.

- Energy & utilities: Enhances efficiency in cooling systems, steam generation, and fluid handling.

- Steel industry: Optimizes cooling water flow and pressure, reducing energy use and equipment wear.

- Water & wastewater management: Provides optimized flow and pressure control.

- Pharmaceuticals: Maintains precise conditions for drug manufacturing.

Real-world use cases

Companies using FOCUS-1 report significant improvements in operational efficiency, cost savings, and maintenance reductions. Some key implementations include:

- Replacing outdated control loops in water treatment plants, reducing installation costs and improving process stability.

- Optimizing flow control in industrial chemical plants, ensuring consistent product quality and reducing energy waste.

- Reducing maintenance downtime in manufacturing facilities by leveraging predictive diagnostics and automated control.

Read more case studies here.

Conclusion

FOCUS-1 is more than just a control valve—it’s an integrated smart device that transforms how industries manage their process control loops. By consolidating measurement, control, and computing power into a single device, FOCUS-1 eliminates inefficiencies, reduces costs, and improves operational accuracy.

Want to know more?

Other blogs that might interest you:

How in Steel Production Smart Meter Valves Reduce Downtime

Discover how ArcelorMittal uses FOCUS-1 smart meter valves to improve flow control, reduce downtime, and detect faults faster in steel production.

The new way of process control with FOCUS-1 in automation

Read about how the FOCUS-1 replaces valves, sensors, and controllers with one smart device while cutting complexity, boosting efficiency, and enabling real-time process control.

How FOCUS-1 saves space, time & energy in process automation

Discover how FOCUS-1 saves space, time & energy by combining flow, pressure, and control functions into one smart device. Simpler setup, better performance.

FOCUS-1 vs. traditional control loops: What’s the difference?

Find out how FOCUS-1 transforms process automation by replacing traditional control loops with an all-in-one smart device. Simplify operations, cut costs, and enhance efficiency with integrated flow, pressure, and temperature control.

FOCUS-1 explained: How this all-in-one smart meter valve replaces traditional control systems

FOCUS-1 is transforming process automation by replacing traditional control systems with an all-in-one smart device. This blog breaks down how it integrates measurement, control, and computing to simplify operations, reduce costs, and enhance efficiency.

How Nobian Tested FOCUS-1’s Functionalities: Precision & Efficiency for Industry 4.0

Discover how Nobian tested the FOCUS-1 Smart Meter Valve, unlocking new levels of precision and efficiency in their operations.