How FOCUS-1 saves space, time & energy in process automation

George Borst

Business Development Lead

March 25, 2025

FOCUS-1 saves space, time and energy at your plant. We are changing the game as efficiency is at the core of every industrial process.

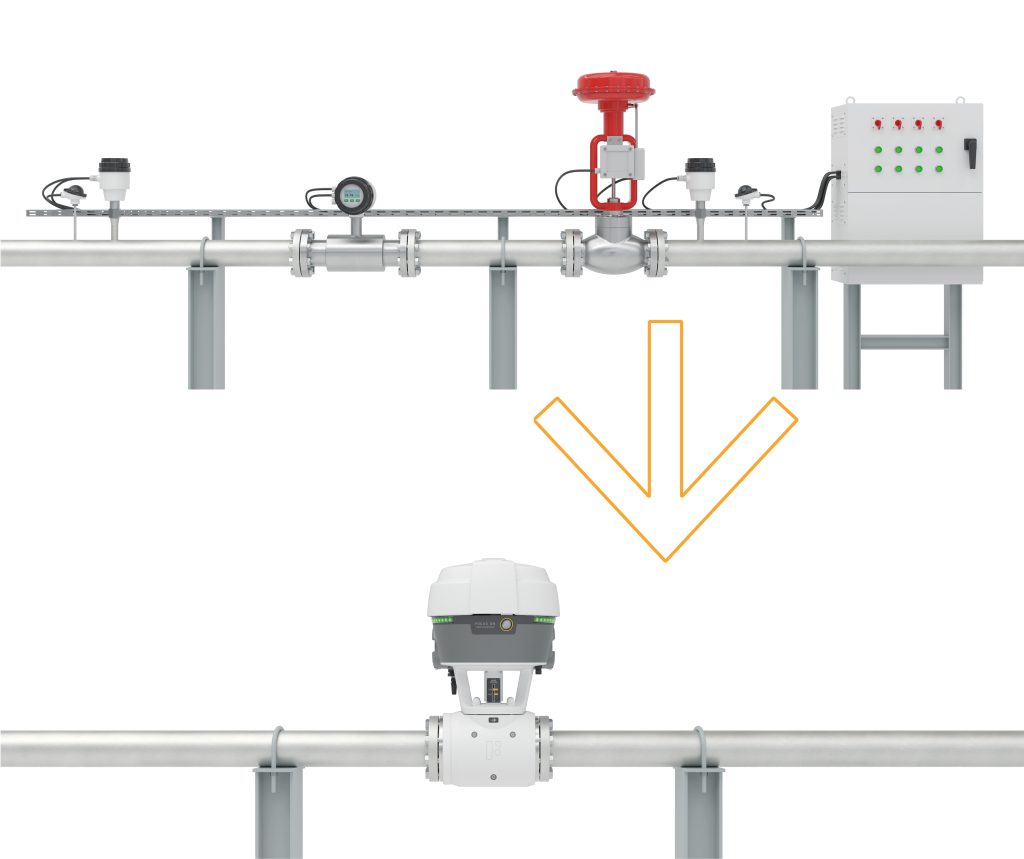

Companies are continuously seeking ways to optimize operations, minimize costs, and enhance sustainability. Traditional process control systems require multiple components, leading to complex installations, high maintenance demands, and increased energy consumption.

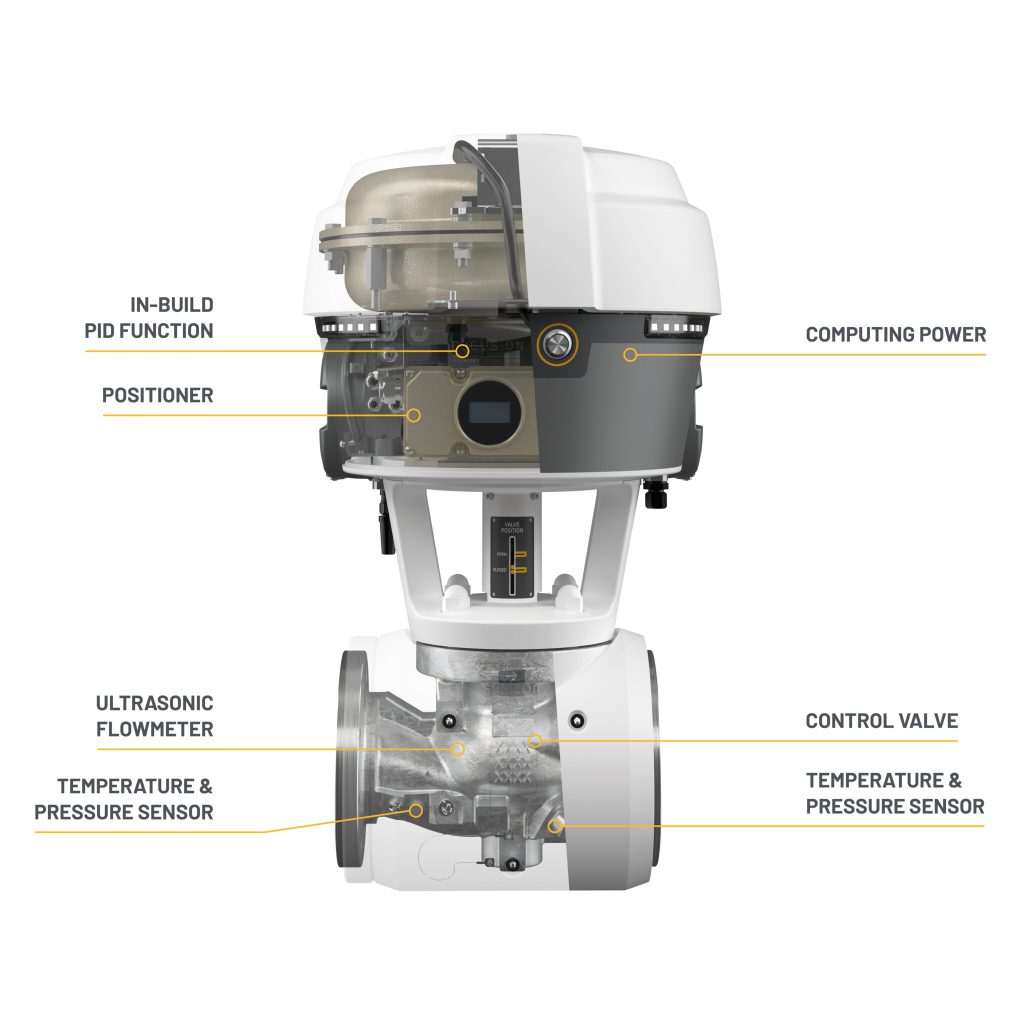

By integrating measurement, control, and computing into the single device of FOCUS-1, it simplifies process automation while delivering substantial savings in space, time, and energy.

The challenge with traditional process control systems

Industrial plants typically rely on multiple separate devices to control flow, pressure, and temperature. This conventional setup presents several challenges:

- Bulky installations: Each system requires multiple flanges, wiring, and sensors, increasing equipment footprint.

- Lengthy installation & setup: Coordinating various devices demands extensive engineering, programming, and calibration.

- High energy consumption: The inefficiency of separate control units results in unnecessary power usage.

- Complex maintenance: Multiple failure points increase downtime and ongoing maintenance costs.

How can industries simplify this and save resources? Meet FOCUS-1.

How FOCUS-1 saves space

One of the most immediate benefits of FOCUS-1 is its ability to reduce the physical footprint of process automation systems.

- All-in-one integration: Instead of installing a separate flow meter, pressure sensor, control valve, and external PID controller, FOCUS-1 consolidates all these components into a single device.

- Fewer flanges & piping: With fewer individual parts to install, the number of flanges is reduced by 4x, minimizing space requirements and cutting down on material costs.

- Less wiring: Since sensors and controllers are integrated, cabling and wiring efforts are significantly reduced, leading to a cleaner and more streamlined setup.

By reducing physical infrastructure, FOCUS-1 allows industries to maximize plant space while cutting down installation complexities and costs.

How FOCUS-1 saves time

Time is money in process industries. The longer it takes to install, configure, and maintain equipment, the higher the operational costs. FOCUS-1 accelerates deployment and simplifies ongoing operations in several ways:

- 33% faster installation: Traditional setups require multiple devices to be installed, wired, and programmed separately. With FOCUS-1, these steps are drastically minimized, reducing overall installation time.

- Plug-and-play configuration: FOCUS-1 is designed to integrate seamlessly with existing automation systems using standard industrial protocols like PROFINET, Modbus, and HART.

- Reduced maintenance downtime: With predictive diagnostics and self-monitoring capabilities, FOCUS-1 detects performance deviations early, helping maintenance teams address issues before they cause system failures.

These time-saving features mean that engineers can focus on optimizing processes rather than troubleshooting equipment failures and inefficient setups.

How FOCUS-1 saves energy

Energy efficiency is a growing concern across industries looking to meet sustainability targets and reduce operational costs. FOCUS-1 optimizes energy usage by improving control precision and eliminating unnecessary power consumption.

- Optimized flow & pressure Control: Traditional systems suffer from overshooting and unnecessary valve throttling, leading to wasted energy. FOCUS-1 precisely regulates flow and pressure, ensuring minimal energy loss.

- Reduced pumping & heating costs: By improving accuracy in temperature and pressure management, less energy is required to maintain optimal conditions.

- Lower heat loss & material waste: With an integrated, streamlined system, less heat dissipation and energy leakage occur, leading to long-term cost savings.

Industries using FOCUS-1 have reported significant reductions in energy consumption, allowing them to meet efficiency regulations while lowering their carbon footprint.

Real-world impact of FOCUS-1

Industries across different sectors have seen tangible benefits from adopting FOCUS-1. Some real-world applications include:

- Chemical processing: Reduction in process variability by up to 40%, leading to energy savings and material efficiency.

- Food & beverage: More stable temperature control, reducing waste and improving batch consistency.

- Water treatment plants: Lower operational costs by reducing pumping energy and improving flow control precision.

- Pharmaceuticals: Faster installation and integration with existing automation systems, reducing downtime in highly regulated environments.

Read more case studies here.

The business case for FOCUS-1

Beyond the technical advantages, FOCUS-1 presents a strong business case for companies looking to enhance profitability while meeting sustainability goals.

- 33% savings on installation costs due to reduced wiring, programming, and components.

- Lower maintenance expenses thanks to fewer failure points and integrated diagnostics.

- Energy efficiency improvements leading to substantial reductions in utility bills.

- Regulatory compliance benefits, making it easier for industries to meet efficiency and environmental standards.

How FOCUS-1 supports sustainability

Conclusion

FOCUS-1 is revolutionizing industrial process control by integrating critical functions into a single, powerful device. By doing so, it significantly reduces space requirements, shortens installation times, and enhances energy efficiency.

For companies looking to streamline operations and improve their bottom line, adopting FOCUS-1 is a smart investment in the future of process automation.

Book your free consultation call today!

Want to read more about FOCUS-1?

Also make sure to read our blogs about: