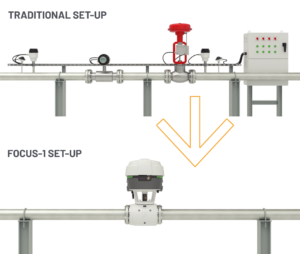

- Easy & Simple Installation due to integration of both measurement and control

- Combined solution enables for fast and rapid control

- A well maintained boiler enables reliable performance and minimizes breakdow

- High-efficiency boilers produces lower emmissions with direct inviormental impact

Background

Dynea is a leader in the European wood adhesives market with a broad portfolio of adhesives for the wood processing industries. Also serving its customer globally in Asia, Africa and the Americas. Dynea headquarters and main site is in Lillestrøm, Norway. Other sites include Dynea Hungary, and Nordalim (Denmark). In addition, we have toll production / contract manufacturing in Germany, Finland, the Netherlands, Austria and Italy. The ambition of Dynea is to build on their existing strong platform growing stimulating more use of wood in construction, and thus enhance the world’s capacity to safely store CO2. This results in the importance of energy usage and storage at all production sites of Dynea.

Control Requirements

An important part of the adhesives production at Dynea is the steam production. By carefully regulating water and steam production Dynea strives to lower their energy consumption which adds to a responsible carbon footprint. In order to maintain a stable and accurate steam production Dynea utilizes boilers. These boilers require a stable and constant flow of feedwater. Depending on the pressure inside the boiler additional water is added. Currently Dynea uses a separate pressure sensor to measure the desired pressure. The optimal value of operation is +/- 2,3 bar. Which does not allow for huge fluctuations. Any fluctuations in pressure are communicated via the DCS to a control valve which regulates the amount of feedwater into the boiler.

There are many important aspects in this process which have a direct impact on the efficiency of the boiler such as, the temperature of the feedwater, the amount of flow into the boiler, etc. Dynea serves the opinion that the more information obtained about this process, the more Dyena is able to optimize and streamline this process. Which directly impact the efficiency of the boiler, the energy consumption of the boiler and ultimately impacts the carbon footprint of Dynea.

FOCUS-ON Solution

By replacing the existing control valve with FOCUS-1, Dynea does not only gain comprehensive control and monitoring capabilities, but also a significant amount of insights into the boiler operation. By now having additional data such as: flow, pressure, and temperature, Dynea can effectively monitor feedwater usage, enhance energy efficiency resulting in a better Carbon Footprint.

An additional important factor for Dynea to choose for FOCUS-1 is its safety aspects. FOCUS-1 ensures that the boiler is supplied with the correct amount of water to maintain safe operating conditions. Inadequate flow can lead to overheating, reduced water levels, and potential damage to the boiler, while excessive flow can cause flooding and other safety hazards. Maintaining the appropriate flow rate helps to prevent these dangerous situations.

To summarize, FOCUS-1 installation supports Dynea with efficient boiler operation, optimize energy usage, and ensure a reliable water supply. This all plays a vital role in safeguarding the boiler system, enhancing its performance, and minimizing the risk of operational issues and safety hazards.

Setup with FOCUS-1

Customer Benefit

Comprehensive control and monitoring capabilities with FOCUS-1

-

- Improved efficinecy of the boil by controling flow regimes and scaling

- Enhanced energy saving and water usage monitoring / reduction

- A well maintained boiler enables reliable performance and minimizes breakdown

- High-efficiency boilers produces lower emmissions with direct inviormental impact

Product used: FOCUS-1

- The Smart Meter Valve For Flow, Pressure and, Process Control

- An All-In-One solution features, control valve, flowmeter, pressure and temperature sensors

- All components are standard SAMSON & KROHNE Devices successfully used for decades

- All sensors are designed redundantly

Contact

Would you like further information about these or other applications?