Developed for the process industry

BASED ON PROVEN COMPONENTS

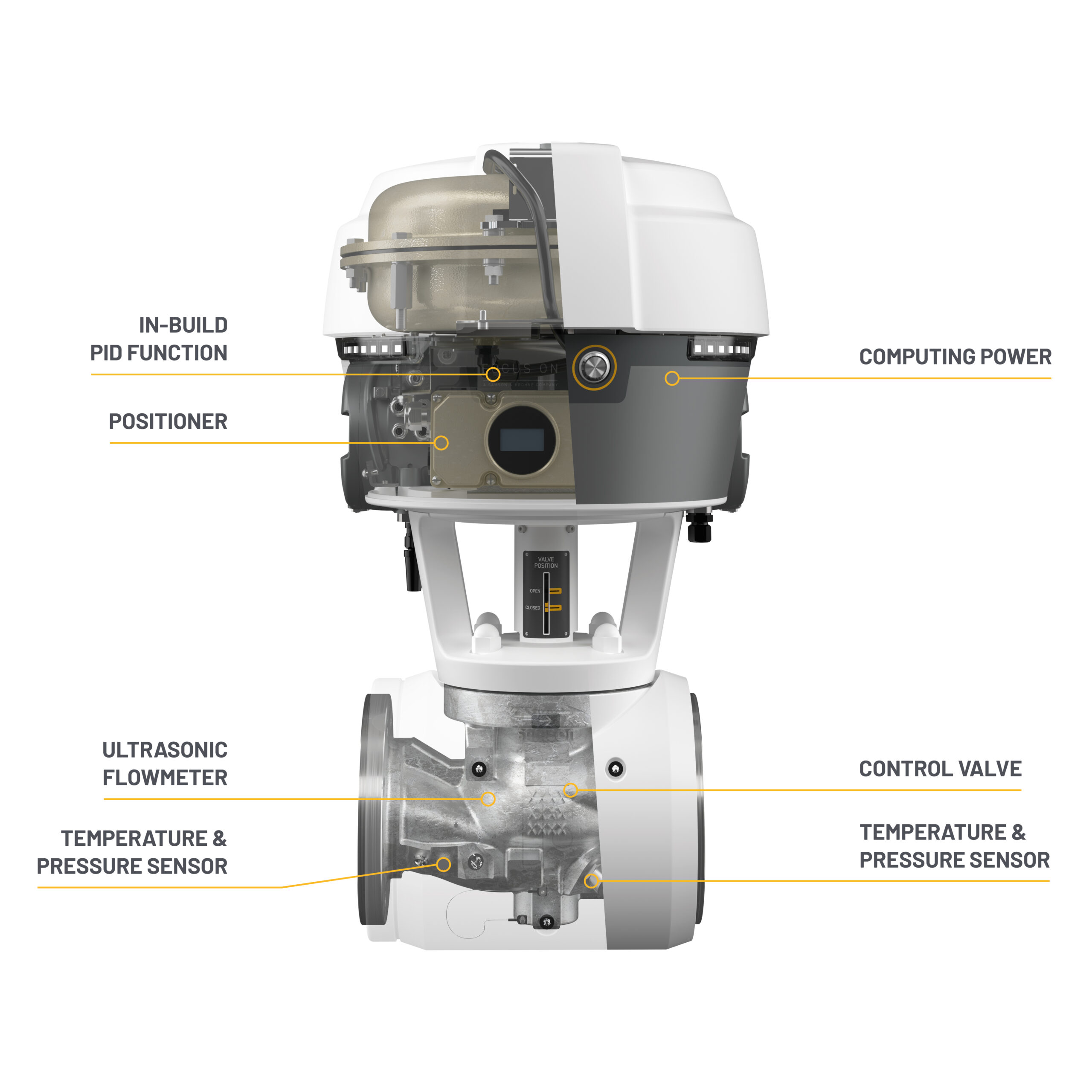

FOCUS-1 is developed for the process industry and features a integrated control valve, flowmeter, pressure and temperature sensors combined with extensive computing power in one single device.

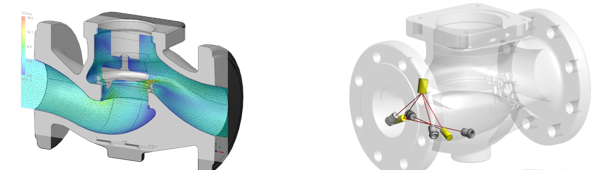

DESIGNED FOR HIGHEST ACCURACY

Extensive CFD analyses enables FOCUS-1 to measure and control a medium between the identical face to face dimensions without jeopardizing on performance compared to a conventional control loop.

MAXIMUM PROCESS AND COSTS TRANSPARENCY

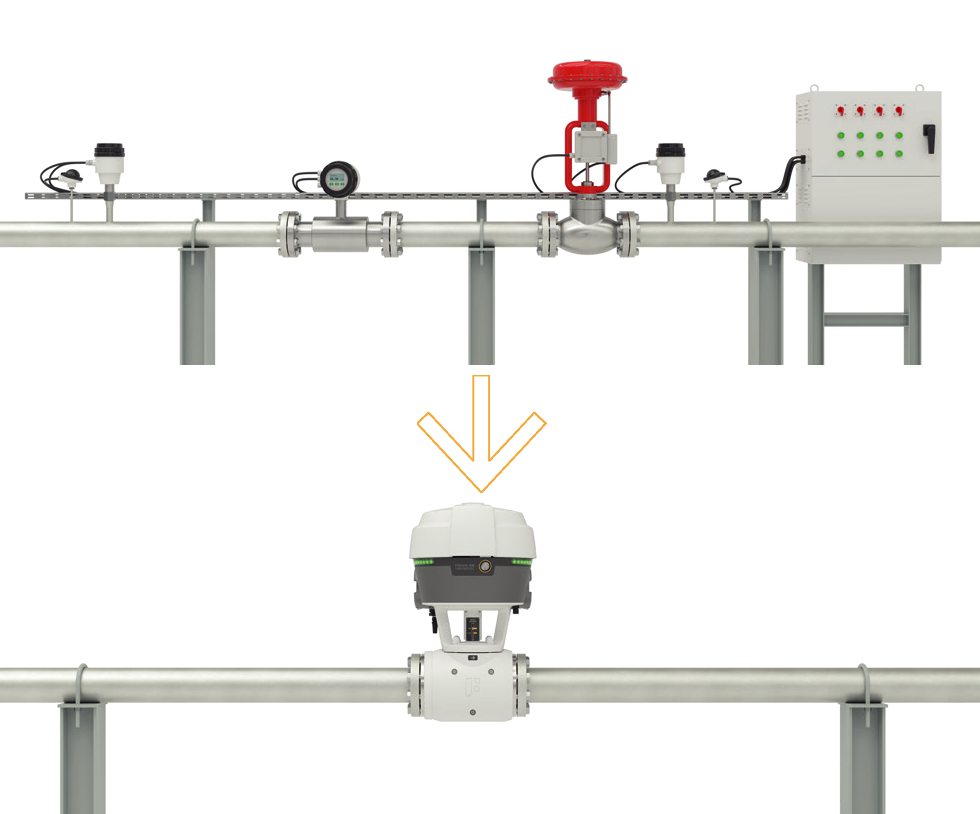

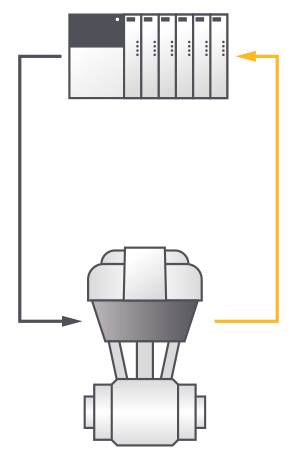

Traditional installations for control tasks in process plants

usually consist of several sensors, a control valve and a

DCS with control algorithms.

The process operator relies on proper functioning of all

these components to ensure process quality.

By combining all these components in one device, FOCUS-1, specifically developed for the process industry,

simplifies the installation dramatically and reduces

significantly the number of flanges, cables and I/O points.

In addition to the above, the commissioning efforts are

also heavily simplified, as all the control algorithms are

implemented within FOCUS–1.

- Save Time and Energy

- Save 33% on installation costs

CLICK & CONNECT

Following the standard

FOCUS-1 complies with various communication protocols which are currently used in the process industry. Both setpoint, measured values as well as alarms can be communicated trough industry standard protocols. This allows the user seamless integration in their existing automation infrastructure.

Easy and intuitive interface

FOCUS-1 can be easily accessed via its in-build web address. This allows remote access, user-friendly interfaces, cross-platform compatibility, scalability, and security, offering several advantages for asset management, maintenance and data control.

Following the standard

FOCUS-1 complies with various communication protocols which are currently used in the process industry. Both setpoint, measured values as well as alarms can be communicated through industry standard protocols. This allows the user seamless integration in their existing automation infrastructure.

Easy and intuitive interface

FOCUS-1 can be easily accessed via its in-build web address. This allows remote access, user-friendly interfaces, cross-platform compatibility, scalability, and security, offering several advantages for asset management, maintenance and data control.

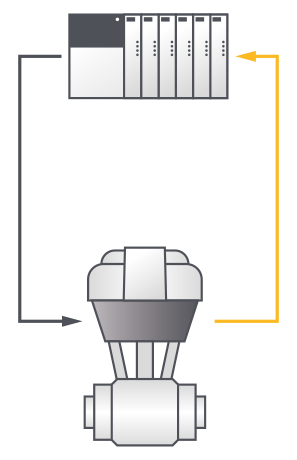

FOCUS-1 simplifies & Improves control

Internal communication between components reduces the need for complex DCS systems. FOCUS-1 can be used depending on control requirements allowing flexibility and adaptivity in various applications. With 1 device any of the below control options can be selected. By using FOCUS-1 as process controller (2) or system controller (3) the build-in PID-(auto) tuner guarantees simple and accurate process control.

POSITION CONTROLLER

Control of the valve position provided by the DCS

Input

- Set point valve

position [%]

Output

- Valve position [%]

- Measured Values

- Alarms

PROCESS CONTROLLER

Control of flow or pressure measured inside FOCUS-1

Input

Set point

- Volumatic flow or

- Outlet Pressure or

- Delta Pressure

Output

- All Measured Values

- Alarms

- Diagnostics

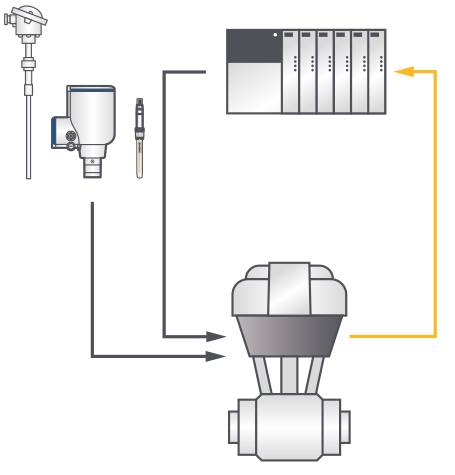

SYSTEM CONTROLLER

Control of process by using a external sensor, such as temperature, level, pH, etc.

Input

- Set point of external

control variable e.g.

temperature or

level or pH

Output

- Set point value

- Measured Values

- Alarms

- Diagnostics

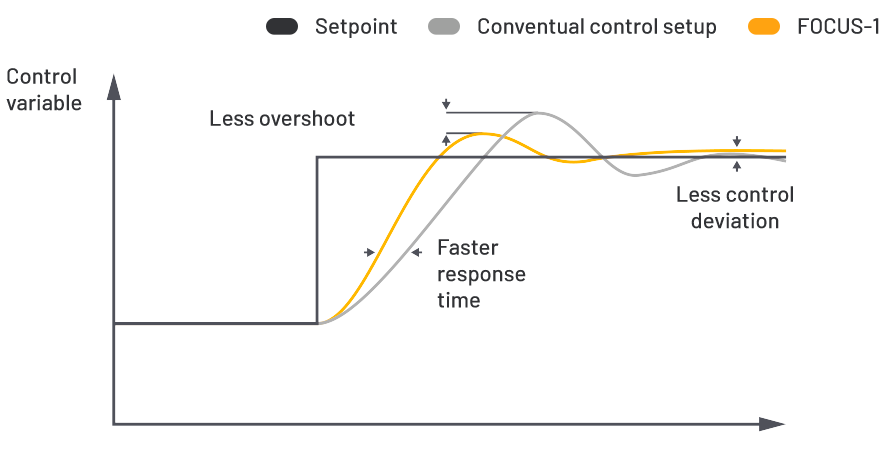

Improved control qUALITY

As all control functions (PID), sensors and the control valve are integrated in FOCUS-1, system accuracy and thus the control quality is significantly improved.

- Setpoints can be reached faster

- Final control deviations can be minimized

- Overshoots reduced to a minimum

The FOCUS-1 Family

| Valve type | Linear globe control valve |

| Flow meter | Ultrasonic transducers |

| Actuation | Pneumatic |

| Fail Action | Fail to Close / Fail to Open |

| Air supply | 3-6 bar clean air |

| Power supply | 85V AC up to 250V AC 18V DC up to 32V DC |

| Input set point | 4-20 mA/ PROFINET |

| Output signal | 4-20 mA (active & passive), HART7®/ PROFINET |

| Area use | non-EX & EX/ATEX |

| Min Inlet run | 4 D |

| Min Out run | 0 D |

| Diameters | DN 50, DN 80, DN 100 (2″,3″ and 4″) |

-

Body Material

-

Trim Material

-

Design Pressure

-

Medium Temp

-

Ambient Temp

-

Seat Bore Size

-

Kv Values

- 1.4408 / ASTM

- 1.4404 / 316L

- 0 – 40 barg

- -40 to 180 degC

- -25 to 55 degC

- 24 / 38 / 48

- 10 / 25 / 40

- 1.4408 / ASTM

- 1.4404 / 316L

- 0 – 40 barg

- -40 to 180 degC

- -25 to 55 degC

- 38 / 63 / 80

- 25 / 60 / 80

- 1.4408 / ASTM

- 1.4404 / 316L

- 0 – 40 barg

- -40 to 180 degC

- -25 to 55 degC

- 63 / 80 / 100

- 63 / 100 / 160

INTELLIGENT DIAGNOSTICS

IMPROVE PLANT UPTIME

The compute model in FOCUS-1 is enhanced with an additional layer of process monitoring, alarming, and diagnosis without compromising safety or performance. This is called the Digital Twin and constantly monitors deviations between measured and modelled values in the compute model. When a deviation of the measured value appears, the device triggers an alarm with information on the possible cause and severity. In the meantime, FOCUS-1 will present the modelled value which allows in having a replaceable process value to continue with operations. Resulting in opportunities to extend and plan maintenance to stops or maintenance beneficial moments.

- Less downtime

- Cost effective integration of safety loops

- More data for process analysis

Case studies

Explore how ArcelorMittal optimized thermal oil cooling with FOCUS-1. Discover the challenges of traditional setups and see how this smart meter valve technology transformed their steel production process, boosting efficiency, reducing costs, and increasing uptime.

Arcelor Mittal

Belgium, Gent

An essential aspect of the biorefinery process involves steam production. Their careful regulation of water and steam production is geared towards reducing energy consumption and ensuring a responsible carbon footprint. A crucial element of achieving this lies in the efficient management of condensate return lines, which transport condensate back to the boiler. A important factor for this process is its safety aspects. FOCUS-1 ensures that the boiler feed water tank with the correct amount of water to maintain safe operating conditions.

George Borst

BDL, FOCUS-ON

Explore how Dynea, a leader in Europe's wood adhesives sector, revolutionized boiler efficiency and sustainability with FOCUS-1, the world’s first smart meter valve.

George Borst

BDL, FOCUS-ON

Discover how a German municipal utility achieved precise tank level control, energy efficiency, and reduced maintenance costs using the FOCUS-1 smart meter valve.

How a German Utility Optimized Water Supply with FOCUS-1

Discover how a leading chemical manufacturer in Antwerpen reduced downtime and improved operational efficiency with the FOCUS-1 smart metering valve. Learn about the challenges faced and the successful strategies implemented.

Eliminating Downtime in Chemical Manufacturing with FOCUS-1: A Case Study

LEARN HOW TO MAINTAIN A MODULAR DEVICE