- Easy & Simple Installation due to integration of both measurement and control

- Combined solution enables for fast and rapid control

- Digitalisation of the asset with real time data

- Direct Temperature input enable fast and accurate temperature control

Background

A global leader in agriculture and food industries, active in over 70 countries uses FOCUS-1 in their gas scrubber applications. Clean gas is very important with regards the current Environmental Regulations and Health & Safety requirements. In the gas scrubber, stable control and accurate measurement is crucial in regards to energy efficiency and process continuity.

Control Requirements

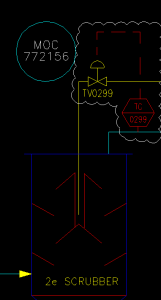

In the scrubber harmful gas is extracted and transported to the incinerator room. The goal of the scrubber is to extract all the harmful gas derived from the processes in the factory by injecting water into the scrubber. The temperature in the scrubber (steam / gas) is crucial for an optimal effect. In this specific application the temperature of the scrubber is maintained by water out of the river the Ijssel at a temperature of approx. 50 degrees. This 50 degrees setpoint is crucial to ensure all the harmful gas are extracted during scrubbing. Currently a temperature sensor on the outlet of the scrubber sends a signal to the Designated Control System (DCS) which calculated the optimal valve position. The Valve will receive it’s setpoint from the DCS and controls accordingly. In the current situation no additional measurements are used for Alarming or Data insight purposes.

Old Valve

FOCUS-ON Solution

By replacing the traditional valve with a FOCUS-1, the process operator maintains all required control & monitoring capabilities. Including additional insights into the gas scrubber. By combining all the measurement & control components in one device, the operator can, based on the data collected by FOCUS-1 decides the best control behaviour regardless of any process condition changes.

In this application the efficiency of the gas scrubber is significantly improved by connecting the temperature sensor directly to FOCUS-1 by using the internal PID parameters. This improvement allows bypassing of the DCS which results to a higher control behaviour in case of set-point changes or change in process parameters. In addition, the operator is informed about the temperature of the cooling water (internal sensor), the flow velocity and the inlet pressure (internal pressure sensor). This allows information to be obtained regarding the influx from the river Ijssel and helps the operator with energy saving calculations. Trough the measurements in FOCUS-1, the operator has more insight in risk of pollution of the filtered water and thus reduces the risk of unanticipated stops due to polluted water.

Setup with FOCUS-1 (PROFINET)

Customer Benefit

- Easy of Installation: With the same build in length of FOCUS-1 the customer has to take little to no efforts during installation. With FOCUS-1 the customer received more insight into various parameters such as temperature of the cooling water, flow velocity, and inlet pressure.

- Improved efficiency: FOCUS-1 significantly improves efficiency by directly connecting the temperature sensor to the device and utilizing its internal PID parameters. This direct control bypasses the need for the Distributed Control System (DCS), eliminating delays and enabling more responsive and efficient control.

- Risk mitigation: With FOCUS-1, the operator gains more information about pollution levels in the water, which can help assess and mitigate potential risks. This allows the operator to stay informed about crucial factors, such as influx from the river Ijssel, facilitating energy-saving calculations and providing insights into water pollution levels and associated risks.

In summary, the benefits of FOCUS-1 in this context include improved control and monitoring capabilities, comprehensive data collection and analysis, enhanced efficiency through direct control, real-time information for informed decision-making, opportunities for energy savings, and better risk mitigation related to water pollution.

Product used: FOCUS-1

- The Smart Meter Valve For Flow, Pressure and, Process Control

- An All-In-One solution features, control valve, flowmeter, pressure and temperature sensors

- All components are standard SAMSON & KROHNE Devices successfully used for decades

- All sensors are designed redundantly

Contact

Would you like further information about these or other applications?