George Borst

Business Development Lead

August 26, 2023

The quest for precision and efficiency has never been more critical in the industrial landscape. As companies strive to embrace Industry 4.0, integrating advanced technologies into their processes is essential for staying competitive. One of the key players in this transformation is the FOCUS-1 smart meter valve, which promises to revolutionize how process industries manage their operations.

In this blog, we explore insights from an exclusive interview with Krystian Pietrzyk and Hans-Juergen Henkel from Nobian, who share their experiences testing FOCUS-1 and the implications for Industry 4.0.

Why Nobian Tested the FOCUS-1

Addressing Industry Challenges

Nobian, known for its innovative approach in the chemical sector, sought to test FOCUS-1 to address key industry challenges such as precision, reliability, and process efficiency. As the industry evolves, so does the need for advanced solutions that can handle complex processes with minimal downtime. Nobian’s goal was to ensure that FOCUS-1 could deliver on these fronts and integrate seamlessly into their existing systems.

Objectives of the Test

The test aimed to:

- Evaluate FOCUS-1’s performance in real-world conditions.

- Assess its integration with existing infrastructure.

- Determine its impact on process control and efficiency.

The Testing Process: Key Focus Areas

1. Installation and Commissioning

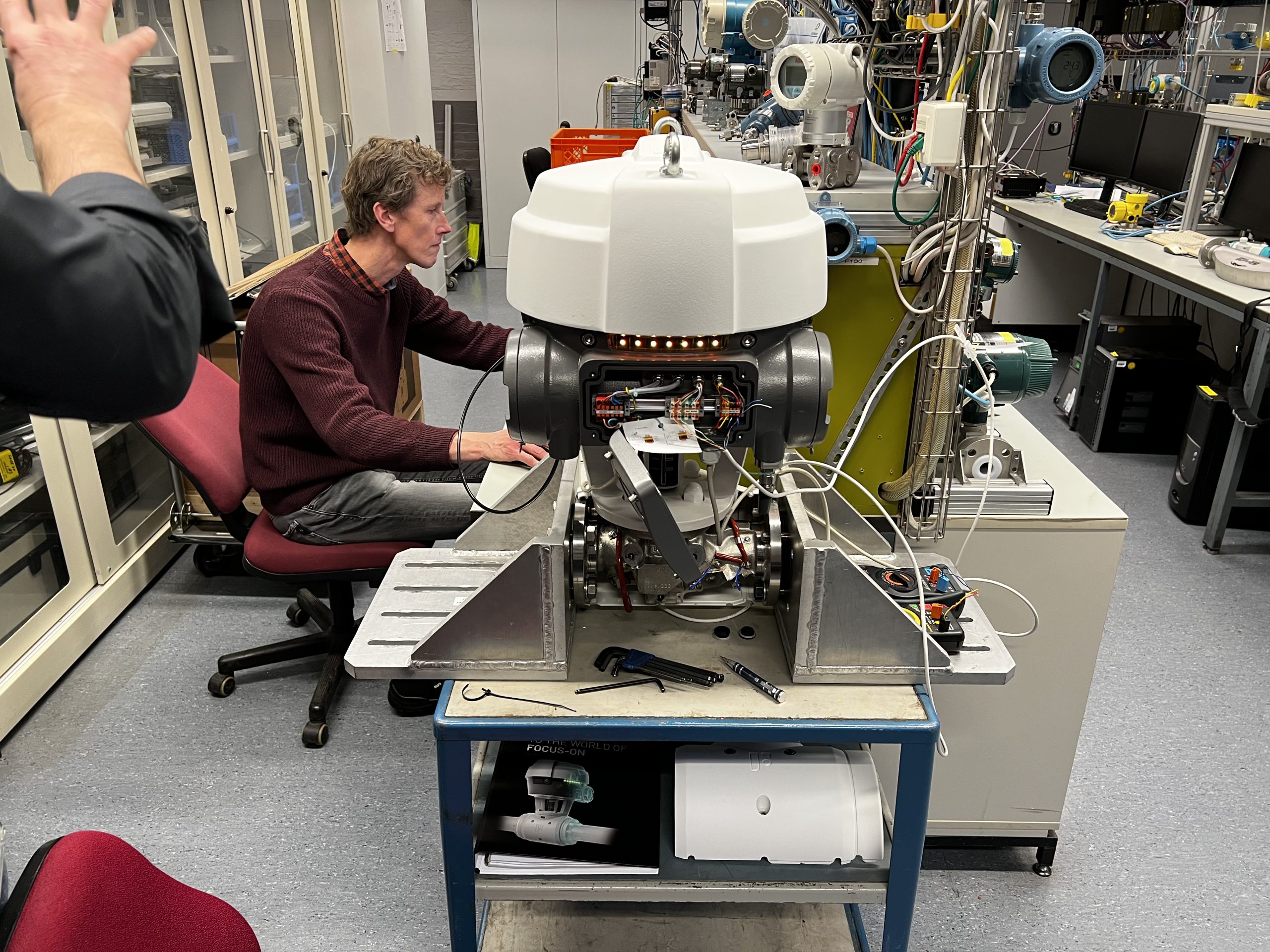

FOCUS-1 was installed alongside standard equipment to compare ease of setup and integration. Nobian found the installation process straightforward, with no significant deviations from traditional devices. Careful handling of cables and sensors was necessary to ensure optimal performance.

2. Functional Stability

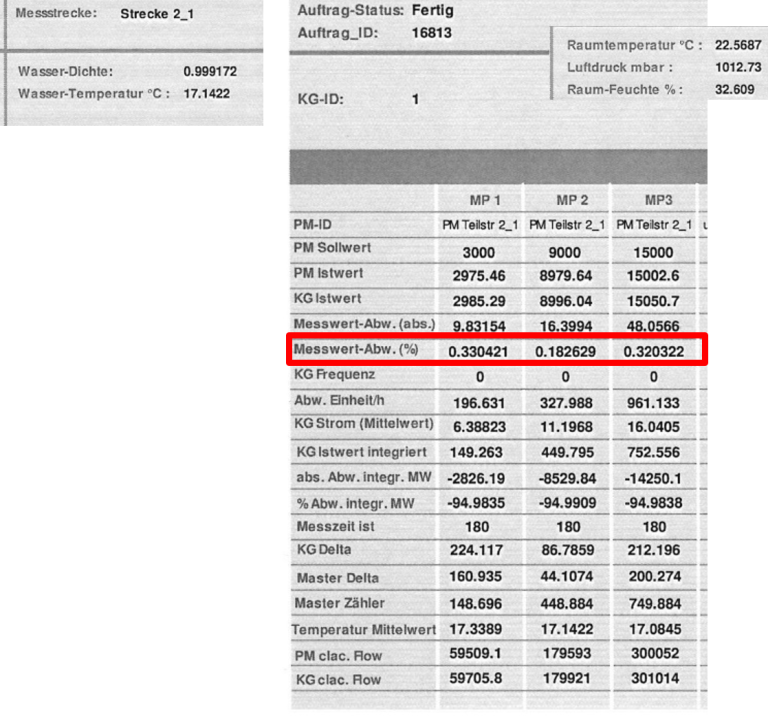

A major aspect of the test was assessing FOCUS-1’s stability and accuracy. The device demonstrated exceptional performance with an uncertainty of just 0.3% at two points and 0.18% at one point. This exceeded the datasheet’s 0.5% promise, proving FOCUS-1’s reliability in harsh chemical environments.

3. Process Control Performance

FOCUS-1’s internal PID controller was evaluated for its effectiveness in managing process control. The device managed control elements with precision, comparable to traditional Distributed Control Systems (DCS). This showed that FOCUS-1 could handle complex control tasks efficiently and reliably.

4. Diagnostics and Maintenance

The test included assessing FOCUS-1’s diagnostic features. The device quickly alerted users to issues with sensors and maintained data accuracy even under challenging conditions. The digital twin technology was particularly notable for its ability to adapt and generate accurate data despite interruptions.

5. Data Collection and Wireless Connectivity

FOCUS-1’s data collection capabilities were tested through various data packages, revealing potential for predictive maintenance and in-depth condition analysis. Its wireless connectivity, including WiFi and MQTT protocol support, allowed for flexible remote configuration and real-time data streaming.

Key Findings and Their Relevance

Enhanced Precision and Stability

FOCUS-1’s ability to provide high precision and stable measurements makes it a valuable tool for process industries. The device’s performance exceeded expectations, offering reliable data and control that can significantly enhance operational efficiency.

Seamless Integration

The ease of integrating FOCUS-1 into existing systems demonstrates its suitability for modern process environments. Its compatibility with traditional and advanced setups ensures that companies can upgrade their systems without major disruptions.

Advanced Diagnostics

FOCUS-1’s diagnostic and maintenance features provide real-time insights that can prevent downtime and improve process reliability. The digital twin technology enhances this capability by offering accurate data even during unexpected conditions.

Data-Driven Insights

The advanced data collection and wireless connectivity features of FOCUS-1 enable more informed decision-making and remote management. This capability is crucial for optimizing process performance and maintaining efficiency.

Conclusion: Why FOCUS-1 Matters for Your Operations

Nobian’s comprehensive testing of FOCUS-1 underscores its potential as a transformative tool for the process industry. With its precision, ease of integration, and advanced features, FOCUS-1 stands out as a key player in advancing process control and efficiency.

Krystian concludes, “FOCUS-1 is the first device we’ve seen that integrates internal control, reliability, and condition monitoring so effectively. It represents a significant step forward for our Industry 4.0 initiatives and offers a model for future innovations.”

For companies looking to enhance their operations, the insights from Nobian’s test highlight FOCUS-1’s capability to deliver reliability and performance. Reach out to us to learn how FOCUS-1 can benefit your specific needs.