Hydrogen will play a significant role within the framework of the energy transition from fossil based fuels to renewable sources. Generation of hydrogen can be done via different routes. One of those is through electrolysis using alkaline electrolysers. The market for alkaline electrolysers is growing rapidly as these installations are often being used in combination with large PV solar fields and wind turbines, with the goal to relieve the electrical power grid. A huge increase in demand means optimization in operation and performance is crucial. Below you will read about how the use of a smart meter valve in alkaline electrolysers reduces cost while also improving functionality and system performance. Sounds to good to be true? Don’t take our word for it: everything you will read is based on proven experience with one of the biggest hydrogen electrolyser producers in the world!

The challenge of the traditional set-up

We can imagine not everyone reads about alkaline electrolysers daily. Let’s dive into how hydrogen is generated by an alkaline electrolyser. This explains the need for a concentration sensor, a flowmeter, a temperature sensor, a control valve and a PLC with the right software. In other words, the usual complex control set-up that might be familiair to you.

What you need to know about alkaline electrolysers

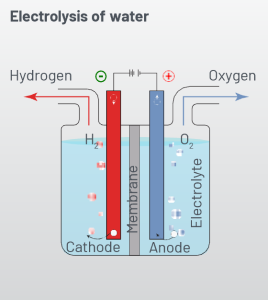

In an alkaline electrolyser hydrogen is generated by splitting water (H2O) molecules in its two base molecules being oxygen (O2) and hydrogen (H2). This can be done by applying an electrical voltage on 2 electrodes inserted in a water filled basin. The water in the basin needs to be electrically conductive, so the electrons, necessary for the reaction, can flow from one electrode to the other. The required and optimum conductivity is achieved by mixing KOH in the demineralized water in the basin.

As the (water splitting) reaction takes place, demineralized water needs to be added (in the right amount) in order to maintain the optimum KOH concentration. As the reaction itself is exotherm the water in the basin needs to be circulated (pumped round) in order to maintain a homogenous temperature distribution and to keep the temperature within limits.

The usual complex control set-up

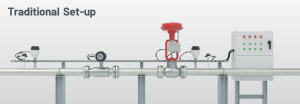

Currently the KOH concentration is measured by (off-line) concentration sensors or deduced by Coriolis mass flowmeters. In both cases their output values go to a PLC, which then operates a valve that controls the inflow of demineralized water in the electrolyser. As the circulation flow of the water/KOH mixture needs to be monitored as well, additionally a flowmeter and a temperature sensor will be installed. Of course, in the case of the Coriolis mass flowmeter the flowmeter would not be strictly necessary.

Reviewing this control set-up there is a concentration sensor, a flowmeter, a temperature sensor, a control valve, and a PLC with corresponding software installed. Requiring all these individual sensors has consequences for the mechanical and electrical construction, installation labor, hardware and software integration in the PLC and likely the dynamic behavior of all these components as one system. In short, a complex system with a challenge to get the dynamic behavior to where it should be and with that open for improvement.

Optimization of alkaline electrolysers

As we already noted, the increase in hydrogen demand is huge. The usual complex control set-up doesn’t allow for comprehensive control and monitoring capabilities, is not efficient enough and is too complex which reduces dynamic behavior and continuous improvement. So how do we fix these challenges while also delivering accurate data insights, high uptime and accurate, stable and fast flow control? Let’s introduce the FOCUS-1.

Eliminating complexity

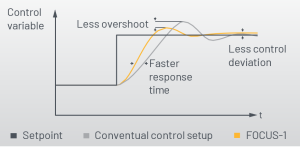

The FOCUS-1 provides a smart meter valve, an ultrasonic flowmeter, temperature sensors and pressure sensors have been integrated with a control valve together with powerful processing, data storage and control capacity. The complexity of the application is eliminated. Now only one single device must be installed and performs the flow control and KOH concentration measurement. As for the (circulation) flow control the integrated (temperature, flow, pressure) sensors are paced at 10 Hz the integrated (PID) control algorithm can drive the control valve very accurately and fast resulting in corresponding process control.

The FOCUS-1 provides a smart meter valve, an ultrasonic flowmeter, temperature sensors and pressure sensors have been integrated with a control valve together with powerful processing, data storage and control capacity. The complexity of the application is eliminated. Now only one single device must be installed and performs the flow control and KOH concentration measurement. As for the (circulation) flow control the integrated (temperature, flow, pressure) sensors are paced at 10 Hz the integrated (PID) control algorithm can drive the control valve very accurately and fast resulting in corresponding process control.

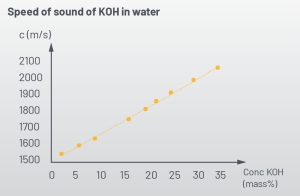

The KOH concentration measurement, necessary to control the demineralised water flow, is an integrated standard feature that is generated by smart combination of available sensor signals (sonic velocity, temperature, pressure). It’s as fast as the other measurements, i.e. 10 Hz, it is very accurate (<0,4% relative uncertainty) and comes as standard feature of the FOCUS-1 smart meter valve.

Smart meter valve customer benefits

In short the benefits of a smart meter valve compared to the familiair traditional set-ups are significant. In this case this is the list of the benefits for one of the biggest hydrogen electrolyser producers in the world:

- Installing only one single device saves on space, installation cost and drives out complexity

- Cost savings resulting from integration of flow measurement, analytic measurement and control in one single device

- Unique fast and accurate KOH concentration measurement integrated

- Optimum control performance and reliability through high measurement frequency and digital twin

- Comprehensive control and monitoring capabilities

- Improved efficiency of electrolyser operation via accurate, stable and fast flow control

- Additional data insights allow for high uptime of electrolyser

Curious about the FOCUS-1 benefits for you?

Would you like further information about these or other applications?

FOCUS-1 used in alkaline electrolyser

- FOCUS-1 DN 50 Smart Meter Valve for Water/KOH circulation flow

- FOCUS-1 DN 50 Smart Meter Valve for demineralized water flow

- FOCUS-1 DN 100 Smart Meter Valve for KOH crossover