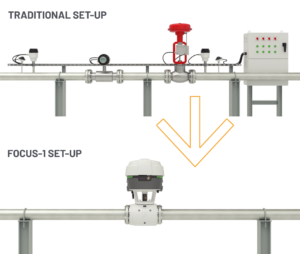

- Easy & Simple Installation due to integration of both measurement and control

- Combined solution enables for fast and rapid control

- A well maintained boiler enables reliable performance and minimizes breakdow

- High-efficiency boilers produces lower emmissions with direct inviormental impact

Background

A leading company Norwegian biorefinery that specializes in utilizing renewable resources, particularly wood, to create sustainable and high-performance products. Their primary focus is on the development and production of biobased chemicals, biochemicals, and biomaterials used in various industries, including agriculture, food, construction, pharmaceuticals, and more. As a leading global player in the biorefinery sector, the company is renowned for its dedication to sustainability, innovation, and responsible practices, contributing significantly to the advancement of green technologies and eco-friendly solutions.

Control Requirements

An essential aspect of the biorefinery process involves steam production. Their careful regulation of water and steam production is geared towards reducing energy consumption and ensuring a responsible carbon footprint. A crucial element of achieving this lies in the efficient management of condensate return lines, which transport condensate back to the boiler. By reusing condensate from various factories to generate steam, the plant effectively maximizes energy efficiency throughout their plant.

Maintaining the boiler feed tank at the correct level is vital for optimal boiler operation. To achieve this, the process employs a valve that acts as a buffer, regulating the pressure and flow of the condensate return. This buffer mechanism prevents the boiler feed tank from running dry, mitigating the risk of boiler overheating, which could cause severe damage to the steam installation.

FOCUS-ON Solution

By replacing the existing control valve with FOCUS-1, this customer does not only gain comprehensive control and monitoring capabilities, but also a significant amount of insights into the boiler operation. By now having additional data such as: flow, pressure, and temperature, the operator can effectively monitor condensate return usage, enhance energy efficiency resulting in a better Carbon Footprint.

An additional important factor for customer is its safety aspects. FOCUS-1 ensures that the boiler feed water tank with the correct amount of water to maintain safe operating conditions. Inadequate flow can lead to overheating, reduced water levels, and potential damage to the boiler, while excessive flow can cause flooding and other safety hazards. Maintaining the appropriate flow rate helps to prevent these dangerous situations.

Setup with FOCUS-1

Customer Benefit

Comprehensive control and monitoring capabilities with FOCUS-1

- Improved efficinecy of the boiler by controling flow regimes and scaling

- Enhanced energy saving and water usage monitoring / reduction

- A well maintained boiler enables reliable performance and minimizes breakdown

- High-efficiency boilers produces lower emmissions with direct inviormental impact

Product used: FOCUS-1

- The Smart Meter Valve For Flow, Pressure and, Process Control

- An All-In-One solution features, control valve, flowmeter, pressure and temperature sensors

- All components are standard SAMSON & KROHNE Devices successfully used for decades

- All sensors are designed redundantly

Contact

Would you like further information about these or other applications?