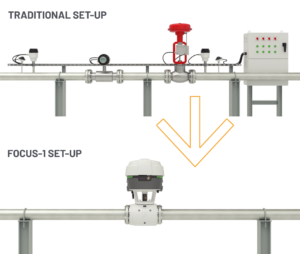

- Easy & Simple Installation due to integration of both measurement and control

- Combined solution enables for fast and rapid control

- Digitalisation of the asset with real time data

- Improved insights into boiler operation, including flow regimes and scaling

Background

Ardo is a global leader specializing in frozen fruit, vegetables, and herbs. With a focus on sustainability, Ardo manage the entire supply chain and offer a wide range of products to retail, foodservice, and industrial customers. Ardo’s production facility in the Netherlands specialize in the processing and production of frozen spinach. Utilizing advanced freezing technologies, they ensure that the spinach retains its freshness, taste, and nutritional properties. The Netherlands location plays a crucial role in Ardo’s supply chain, supplying frozen spinach for retail, foodservice, and industrial customers.

Control Requirements

At Ardo in the Netherlands, steam produced in a boiler is used to cook spinach before its frozen, this to maintain the quality and extend shelf life. During operations an optimal control and monitoring of the boiler feed water is crucial for several reasons. It ensures efficient heat transfer, preventing corrosion and scaling which impacts the lifespan and efficiency of the boiler. Proper water control enhances safety by maintaining optimal operating conditions.

At Ardo the current control valve used was leaking and also did not use measurements to monitor efficiency and water usage of the boiler. Additionally, Ardo is looking for instruments which can help to reduce downtime, especially during harvest period where continuous operation is necessary to keep the quality of the product at high standards.

FOCUS-ON Solution

By replacing the existing control valve with FOCUS-1, Ardo gains comprehensive control and monitoring capabilities, offering valuable insights into the boiler operation. Previously lacking flow, pressure, and temperature sensors, Ardo can now effectively monitor water usage and enhance energy efficiency.

The implementation of FOCUS-1 enables Ardo to better understand flow regimes during operation and identify scaling issues in continuous operation. Investing in FOCUS-1 demonstrates Ardo’s importance for continuous operation by leveraging and utilizing FOCUS-1 diagnostic capabilities. For instance, FOCUS-1 can detect valve leakage, allowing Ardo to plan maintenance during the winter period when there is no harvest.

Overall, FOCUS-1 provides Ardo with enhanced information and diagnostics, improving operational efficiency and instilling trust in continuous boiler operation.

Setup with FOCUS-1

Customer Benefit

Comprehensive control and monitoring capabilities with FOCUS-1

-

- Improved insights into boiler operation, including flow regimes and scaling

- Enhanced energy efficiency and water usage monitoring

- Diagnostic capabilities for detecting issues like valve leakage

- Improved efficiency, trust, and planning for continuous operation

Product used: FOCUS-1

- The Smart Meter Valve For Flow, Pressure and, Process Control

- An All-In-One solution features, control valve, flowmeter, pressure and temperature sensors

- All components are standard SAMSON & KROHNE Devices successfully used for decades

- All sensors are designed redundantly

Contact

Would you like further information about these or other applications?