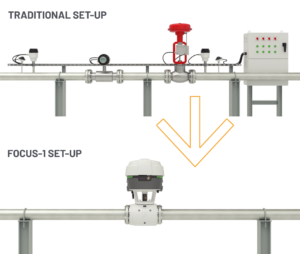

- Easy & Simple Installation due to integration of both measurement and control

- Combined solution enables for fast and rapid control

- Control intervention between FOCUS-1 devices maintains buffer tank level, promoting a balanced microorganism colony.

- Diagnostic features, including a digital twin and insights into valve status, enhance continuous operation and facilitate efficient maintenance planning.

Background

Heros Sluiskil B.V. is a Dutch company specializing in waste processing and recycling, particularly incinerator bottom ash (IBA). They operate an advanced facility in Sluiskil, Netherlands, focusing on sustainable waste management and resource recovery. Their state-of-the-art technologies extract valuable materials from waste streams, contributing to a circular economy. This so-called bottom ash is non-incinerating material and are reused as a resource. Examples of these products are steel, glass, etc which are reused at other companies which bring it back into valuable products.

Control Requirements

Water plays a vital role in Hero process. The company utilizes water to separate valuable materials from unusable ones. However, after separation, the water cannot be reused or discharged into the sewer without undergoing treatment. In the final stage of the process, known as RWZI, the water undergoes treatment with microorganisms. These microorganisms break down harmful substances, making the water reusable or suitable for disposal in the sewer. Maintaining a proper balance between the volume of water and the microorganism colony is crucial for effective operation. Accurate dosing is essential to prevent the death of microorganisms, which can lead to process delays while the colony is reestablished. Previously, the customer used separate components (control and measuring elements) without detailed information about their status, data and diagnostics. Implementing a focused approach provided better control and insight into continuous operations.

FOCUS-ON Solution

By implementing FOCUS-1, Heros achieves the integration of a flowmeter and valve into a single device, eliminating the need for separate components. The integrated flowmeter ensures exceptional accuracy, with only a 0.5% level of inaccuracy, enabling precise flow control into the basins. Through an internal PID controller, the flowmeter communicates directly with the valve, facilitating direct flow regulation without relying on DCS intervention. This direct control action significantly improves speed and efficiency compared to conventional setups used in the past.

Heros utilizes two basins and employs control intervention between the two FOCUS-1 devices to maintain an optimal level in the buffer tank, ensuring a balanced microorganism colony. In conjunction with other measurements, such as pressure sensors, Heros can effectively monitor pollution in the pipeline, providing valuable insights for continuous operation.

Continuous operation is crucial for successful water cleaning, and FOCUS-1 incorporates important diagnostic features that contribute to Heros’ goal. One notable feature is the digital twin, which eliminates the need for physical redundancies to ensure accurate flow measurement and dosing. The digital twin compensates for any measurement discrepancies through a computer model, utilizing other measurements as a reference. Additionally, FOCUS-1’s diagnostic capabilities enable the measurement of valve leakage, cavitation, air pressure, and more. This information empowers Heros with enhanced insights for continuous operation and facilitates more informed maintenance planning, allowing for maintenance to be conducted during feasible moments, such as planned stops.

Setup with FOCUS-1

Customer Benefit

- Integration of flowmeter and valve in FOCUS-1 eliminates separate components, streamlining the system.

- Achieves precise flow control with an exceptional accuracy of only 0.5%, ensuring optimal dosing.

- Direct communication between flowmeter and valve enhances speed and efficiency compared to conventional setups.

- Control intervention between FOCUS-1 devices maintains buffer tank level, promoting a balanced microorganism colony.

- Diagnostic features, including a digital twin and insights into valve status, enhance continuous operation and facilitate efficient maintenance planning.

FOCUS-1 integration achieves precise flow control, improves efficiency, balances operations, and enhances maintenance planning, benefiting Heros with streamlined processes and optimized performance.

Product used: FOCUS-1

- The Smart Meter Valve For Flow, Pressure and, Process Control

- An All-In-One solution features, control valve, flowmeter, pressure and temperature sensors

- All components are standard SAMSON & KROHNE Devices successfully used for decades

- All sensors are designed redundantly

Contact

Would you like further information about these or other applications?