- Easy & Simple Installation due to integration of both measurement and control

- Combined solution enables for fast and rapid control

- Accurate insights into flow ramp-up and efficient decreasing of the loading flow

- Direct flow control for fast and efficient loading

Background

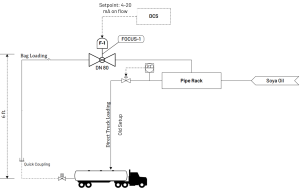

A global leader in food processing and commodities trading, focusing on agriculture has a longstanding history in various segments, including oilseeds processing, corn processing, agricultural services, and more. Company sources, processes, and distributes agricultural products like grains, oilseeds, and food ingredients. With one of the locations, situated in Rotterdam, The Netherlands, Soya Oil is produced for the consumer market. After the refining process, an important part of the production process, transfer of the soya oil from the production plant to customer is executed via trucks, trains or other transportation methods. In this case FOCUS-1 is used to control the flow of soya oil into the truck for logistics purposes. A very important and diligent process to maintain product quality.

Control Requirements

In the past a separate flowmeter and valve system for filling soy oil into trucks was used. However, for this specific application, there is an increased need for efficient and accurate flow control. To guarantee a safe and efficient bag loading process, preventing bag rupture, spills, and leaks, precise flow control is crucial. It is essential to load the oil uniformly without agitation, maintaining its integrity and preventing foaming or degradation. This becomes even more critical as the loading bags can vary shape which influence product streaming profile during loading. The specific requirement entails gradually increasing the flow rate as the bag fills, starting low (around 200 l/min), increasing to a higher rate (around 1000 l/min), and finalizing with reducing the flow rate again (around 200 l/min) when the bag is around 80-85% filled.

FOCUS-ON Solution

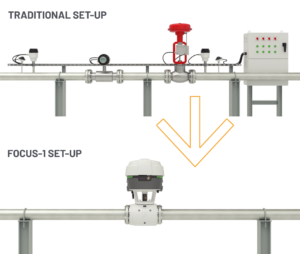

By implementing FOCUS-1, combination of flowmeter and valve into a single device is achieved, eliminating the need for separate components. With a same face-2-face build, there is no necessity for any cutting, grinding or welding. This resulted in a cost savings of over 33% for mechanical installation by reducing the number of flanges, cables, and other materials required but also on electrical installation by simplifying the automation infrastructure.

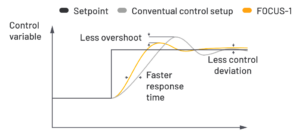

The integrated flowmeter achieves an inaccuracy of only 0.3%, enabling precise flow control and ensuring safety with the inclusion of an integrated pressure sensor. The flowmeter is communicating directly to the valve through an internal PID controller. Enabling direct flow regulation without relying on DCS intervention. This direct control action improves speed and efficiency compared to the conventional setup used in the past.

The pressure sensor serves as an indicator, detecting any issues during loading, such as bag rupture, prompting necessary action. FOCUS-1 provided the customer with a comprehensive solution that fulfilled their automation and control requirements, resulting in accurate, safe, and efficient bag loading while minimizing the risk of losses or bag breaks.

Setup with FOCUS-1

Customer Benefit

- Integration of flowmeter and valve into a single device (FOCUS-1) resulted in cost savings of over 33% for installation and automation expenses.

- The integrated flowmeter offers high accuracy of 0.3%, ensuring precise flow control during the loading process. Direct connection between the flowmeter and valve through an internal PID allows for faster and more efficient flow regulation, eliminating the need for external control systems.

- Integrated pressure sensor enhances safety by detecting issues such as bag breaks and enabling prompt action to prevent spills or leaks.

- Simplified installation and fewer components lead to easier maintenance and reduced downtime for the customer.

- With a integrated dashboard the customer can easily generate reports about FOCUS-1 diagnostics for maintenance and filling profiles in the past 12 months.

Overall, FOCUS-1 offers an accurate, safe, and efficient solution for bag loading, enhancing productivity and reducing operational risks.

Product used: FOCUS-1

- The Smart Meter Valve For Flow, Pressure and, Process Control

- An All-In-One solution features, control valve, flowmeter, pressure and temperature sensors

- All components are standard SAMSON & KROHNE Devices successfully used for decades

- All sensors are designed redundantly

Contact

Would you like further information about these or other applications?