George Borst

Business Development Lead

August 02, 2024

In factories and industrial plants, the traditional process control loop plays a vital role in control systems, utilising multiple components such as a process sensor, controller, and final control element (FCE) to achieve a desired process variable. However, these components take up a lot of space and are prone to failure. The recent emergence of smart meter valves is transforming this space, introducing advanced technology that improves efficiency and reduces costs.

In this blog, we will explore the transformative impact of smart meter valves and highlight their distinct benefits and key differences from conventional process control. We aim to showcase how smart meter valves promise a future of smarter, more efficient factories.

Traditional Process Control

Traditional process control, although it may not be specifically termed as such in industrial contexts, is comparable with finding the right shower condition.

The shower analogy

Imagine you’re in the shower, adjusting the knobs to control the water flow. Using the knob you find the right water speed. The knob directly functions as a valve and based on your senses you accept a specific opening to enjoy the right shower condition. In the beginning of process control adjusting a valve with the hand was the basis of flow control but overtime this has developed due to achieve a production level of consistency, economy and safety which could not be achieved purely by human manual control.

Early automation

To achieve a production level of consistency and safety the process industry started to automate this processes. First with semi-automation with inventions like steam boilers, but after the industrial revolution the real impact was made trough industrial controllers. The evolution of industrial automation accelerated rapidly as factories began making use of relay logic and underwent electrification – the process of powering by electricity. This made the demand for instruments and controllers grow.

Technological Advancements

As safety and consistency became more important also technological developments arose. In the 1930s, controllers were introduced into the industry to enable calculated changes as a response to disturbances from the set point. Solid-state digital logic modules for hard-wired programmed logic controllers were being adopted by industrial control systems for process control and automation in 1958. Since then these controllers have become digital but the basic of the logic controllers are still used in Traditional process control as we know it.

The rise of digital controllers

In industrial automation terminology, the digital controller is integrated in a computer also known as a PLC (Programmable Logic Controller). The PLC interprets setpoint commands and controls the operation of the valve based on the output of the flowmeters deviation of the setpoint. This eliminates the need for manual adjustment of the valves, akin to manually adjusting the buttons on a shower to regulate water flow.

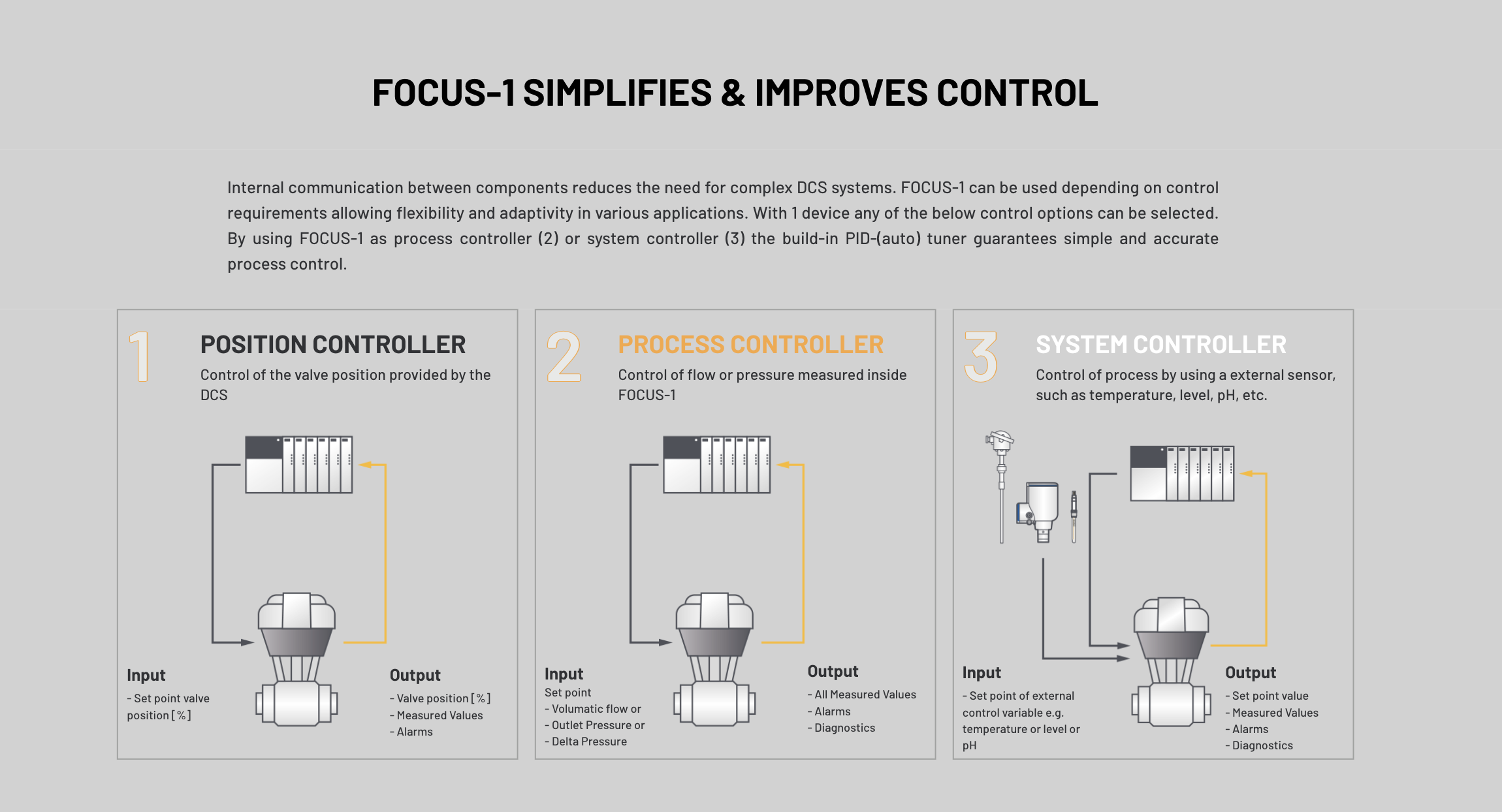

Smart Meter Valves

Smart meter valves, also known as intelligent or digital control valves, leverage computing power, sensors, control valve, and communication to optimise industrial processes. At their core a smart meter valve exists out of a control valve with integrated flow meter, pressure, and temperature sensors and a robust computer. This innovative setup simplifies process control compared to traditional methods, offering precise regulation of flow rates, pressure and other process variables.

Advantages

These advanced valves offer several benefits, enhancing operational efficiency and optimising resource utilisation while maintaining consistent product quality. Utilising cutting-edge technology, the use of smart meter valves simplifies the process control loop by installing and connecting a single device.

Build, Calibrated, and Initialised Device:

- The smart meter valve is specifically designed to perform control on the measured process value.

- It can control flow or pressure directly with exceptional accuracy.

Autonomy and Automation:

- The smart meter valve allows for autonomous control of the required process variable using a computer as the controller.

- Alternatively, it can be integrated into an automation structure with a PLC, where the setpoint is sent for the desired process variable.

Streamlined Process Control Loop:

- With an integral approach, the smart meter valve simplifies the construction of a process control loop, significantly reducing complexity.

Data Accessibility and Analysis:

- Access to data from the smart meter valve enables predictive maintenance, ensuring timely interventions.

- It also facilitates regulatory compliance and provides valuable data for process improvement analysis.

Application

Smart meter valves find applications across various industries, controlling parameters such as pressure, flow, level, and temperature. Their versatility and effectiveness contribute to making industrial processes smarter and more efficient.

To learn more about Focus-ON’s smart meter valves and how they can benefit your operations, click on this link.

Key Differences ‘Traditional’ and Smart Meter Valves

Smart meter valves represent a significant advancement in industrial automation, offering several key advantages over traditional valves. Let’s explore these differences in detail:

1. Easy Installation and Setup

Unlike traditional valves that require complex engineering and setup, smart meter valves simplify the process by integrating all components into one device. This streamlined setup reduces the need for extensive engineering work, making installation quick and straightforward.

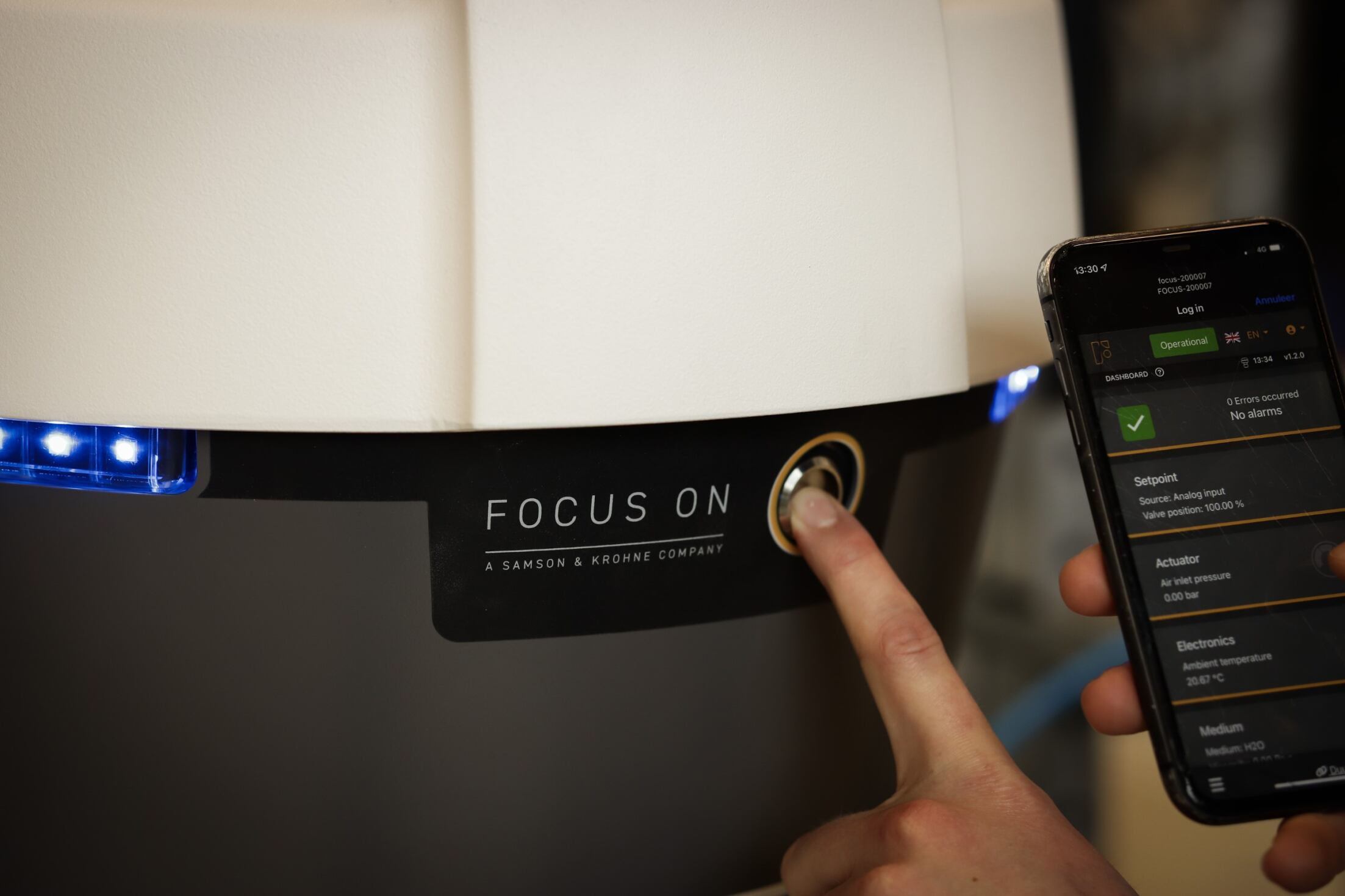

2. User-Friendly Controls

Smart meter valves feature a intuitive connection option like the use of smart devices, making them easier to operate compared to traditional components. Operators can adjust settings and issue commands with ease, resulting in smoother and faster operation.

3. Better Control and Accuracy

Smart meter valves excel at precise control, leveraging advanced methods and real-time data to ensure smooth operation. They can accurately regulate flow rates and pressure, enhancing overall process efficiency and reliability. A Smart meter valve is able to do this more accurate & faster then the most common traditional setup.

4. Built-In Diagnostics and Maintenance

Smart meter valves come equipped with diagnostic tools that can detect problems and collect data without manual intervention. These tools monitor valve performance and alert operators or maintenance team to issues, facilitating proactive maintenance and reducing downtime.

5. Backup Plans with Digital Tech

In the event of sensor failures or malfunctions, smart meter valves utilise digital models and algorithms to maintain operation smoothly. This backup system ensures continuity in operations, minimising disruptions and downtime.

In summary, smart meter valves offer significant advantages in terms of ease of installation, user-friendliness, control accuracy, diagnostics, and backup systems. By leveraging these benefits, industries can enhance process efficiency, productivity, and reliability.

Benefits of Switching to Smart Meter Valves

1. Precision Control

Smart meter valves offer precise control over critical factors such as flow rates, pressure, and temperature. This ensures consistent product quality and maximises resource utilisation across industrial processes.

2. Advanced Monitoring and Diagnostics

Equipped with built-in monitoring and diagnostics, smart meter valves provide real-time insights into system performance. This enables operators to quickly identify and resolve issues, minimising downtime and optimising asset management which can lead to saving more costs.

3. Cost-Efficiency

Trough a integrated setup it is more simple and cost effective to install a smart meter valve compared with a traditional setup. Its is easier to build in and connect to a PLC system without the need to build a control loop algorithm.

4. User-Friendly Design

Featuring intuitive interfaces and configuration, smart meter valves enhance operational efficiency and minimise errors. This user-friendly design caters to all levels and functions within a process plant so that all personal do not need specific skill levels to interact with a smart meter valve, facilitating smoother and more streamlined processes.

5. Future-Proofing

By embracing smart meter valves, industries position themselves for future automation trends. This ensures sustained relevance and competitiveness in the long term, enabling organisations to adapt to evolving technological advancements seamlessly.

In summary, smart meter valves offer precision control, advanced monitoring, cost-efficiency, user-friendly design, and future adaptability. Leveraging these benefits, industries can elevate operational performance, drive efficiency, and maintain competitiveness in the market.

For more information on smart meter valves and their benefits, download our comprehensive guide here.

Real life examples

In today’s energy market, optimising electrolysis processes is vital for the shift towards renewable energy sources. Let’s delve into the impact of smart meter valves on this sector.

Application in energy industry

Picture a scenario where FOCUS-1-powered smart meter valves are revolutionising electrolysis efficiency. By seamlessly integrating flow measurement, analytics, and control into a single device, they streamline operations and boost performance. With ultrasonic flow meters, temperature, and pressure sensors seamlessly integrated, installation becomes a breeze, eliminating complexity. This guarantees precise control over KOH concentration and circulation flow, leading to significant cost savings and enhanced system functionality.

Explore the full case study here.

Application in chemical industry

Now, let’s delve into the chemical industry, where the meticulous management of condensate return lines plays a pivotal role in ensuring the safety and efficiency of boiler operations. Consider the case of a leading biorefinery in Norway, which has embraced the innovation of FOCUS-1 smart meter valves.

By replacing traditional control valves with FOCUS-1, the biorefinery has gained comprehensive control and monitoring capabilities. With access to real-time data on flow, pressure, and temperature, operators can optimise condensate return usage, resulting in reduced energy consumption and environmental impact.

Furthermore, FOCUS-1 ensures boiler safety by maintaining optimal water levels, thereby preventing breakdowns and ensuring reliable performance. With its seamless integration of control valve, flow meter, and sensors, FOCUS-1 offers a holistic solution for enhancing boiler efficiency and sustainability. For further details on this case study, click on this link.

To explore more case studies showcasing the successful implementation of smart valve meters across various industries, click on this link

Conclusion

In conclusion, smart meter valves represent a significant advancement in process control technology, empowering industries to achieve unprecedented levels of efficiency, reliability, and simplification. To explore the transformative potential of smart meter valves for your operations, visit our website and discover our innovative solutions and real-world case studies. Contact us today to revolutionise your process control and automation strategies. Let’s embark on this journey towards enhanced efficiency and productivity together!